First, lots and lots of cutting. Erin created about two dozen patterns, each corresponding to feathers from actual northwest bird species. They ranged from tiny to over a foot long. Here, I'm scoring a crow feather.

This is the crow feather, fully cut out. Most of the time they broke out in one piece, but some shapes were certainly easier than others.

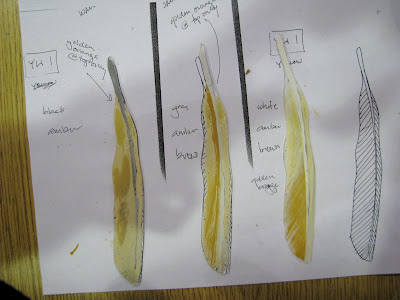

We quickly found that for ease of production is was most efficient to paint in stages. Often, we had many batches going at once, allowing our paints to dry before each additional layer was added.

Once the feathers were painted, they needed texture added. By carving quills and veins (barbs!) into refractory, we created molds. This was also a messy, time consuming project. Here are a few molds.

Once the feathers were patterned using the mold, they were nearly done.

Now all that remained was to slump the feathers into molds, to give them curvature they'd need for realism. At this point it was gratifying to see lots of pieces approaching completion.

Once colored, textured and bent, the feathers were nearly ready for installation. Our part was pretty much done at this point.

We're now anxiously awaiting some photos of the finished installed piece!